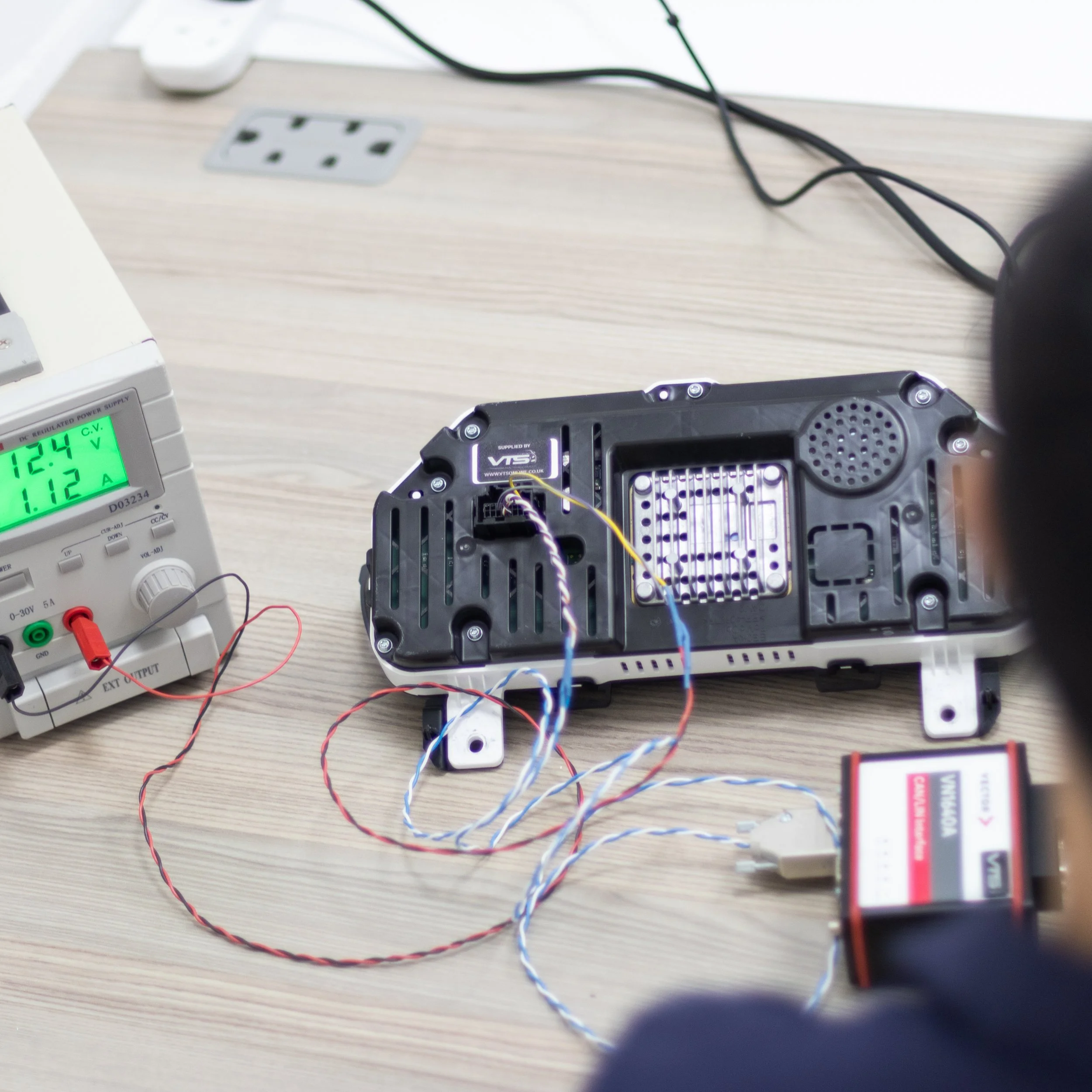

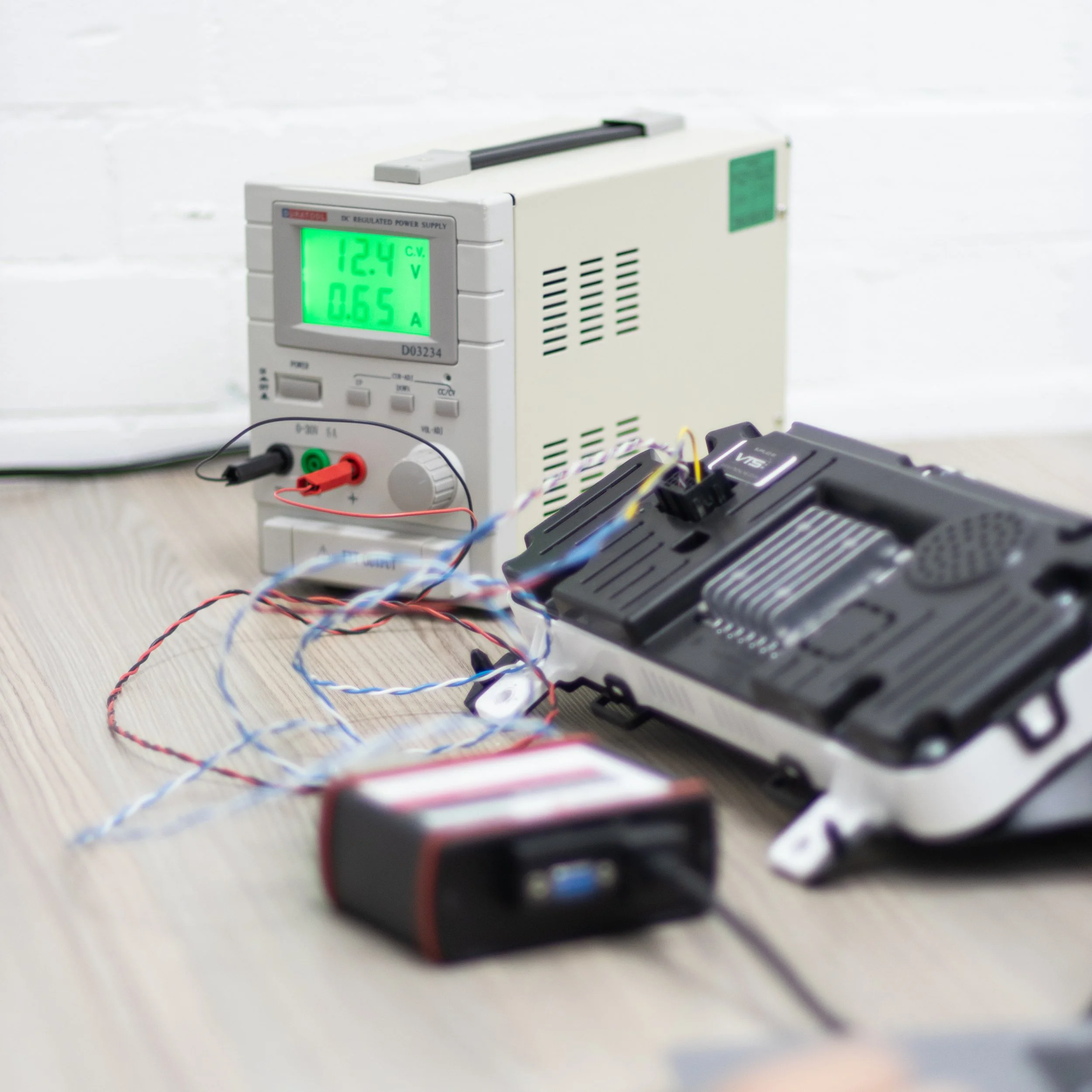

Component Testing

Component Testing for ECUs Before Vehicle Integration. Validate module behaviour early with standalone ECU testing. We verify diagnostic response and communication behaviour against defined criteria, so issues are found before they reach the vehicle build.

Validated the component? See how we support full System Integration Testing before vehicle sign-off.